Product Testing

A key function of the Centre of Excellence is the continual testing of Fenner belting products to ensure that the very highest standards are met. Conveyor belting, particularly for use in underground applications, is subject to rigorous safety testing in our state-of-the-art facilities to ensure that all belts meet the most stringent requirements.

Our in-house dynamic performance testing ensures that every belt is fit for purpose.

Safety testing

The Fenner approach to fire safety testing is based on the premise that a belt should never be the cause of a fire, should be difficult to ignite, and if ignited by an external fire source, should not propagate the fire. Whilst fire resistance specifications vary from country to country, Fenner belts can be formulated to meet any fire performance specifications in the world. The tests carried out on conveyor belts to assess their compliance with fire safety standards are associated with four particular hazards.

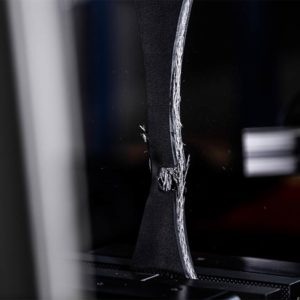

1. Drum Friction Test

The danger associated with a stalled belt and a driven rotating drum or pulley resulting in frictional heat build-up. A test piece of conveyor belt, suitably mounted and tensioned, is wrapped halfway around a rotating steel drum, simulating a stalled belt. The test is continued at specified tensions for a given time period, or until the belt breaks. The presence, or absence, of flame or glow, is noted and the temperature of the drive drum is measured. The test is conducted in still air and/or in moving air. This test has probably been the major single contributor to mine safety in respect to conveyor fire prevention.

2. Laboratory Flame Test

The possibility of igniting the considerable mass of a conveyor belt with a relatively small ignition source. This hazard is usually assessed by the application of a small “Bunsen” type flame to a belt sample and observation of the effect. The time taken for all flame and/or glow to self-extinguish is noted.

3. Gallery Fire Test

The possibility of a belt, ignited from a larger ignition source, spreading the fire to other areas (often referred to as fire propagation). This hazard can only be assessed by a gallery fire test. Historically, this was a large scale test that involved the use of 7.5kg of propane over 50 minutes to ignite a belt. Whilst the testing method was robust, the test itself required large scale facilities and created environmental and health and safety issues. In 2002, Fenner provided assistance for the UK Health and Safety Executive’s development of the mid-scale high energy test. Accurate correlation with the large gallery test was achieved and this test was incorporated into the European Standards. Fenner’s in-house test facility is the only such one in operation in the UK.

4. Electrical Resistance Test

The possible build-up and subsequent discharge of static electrical charge on moving conveyors. Fenner’s PVC and rubber compounds are specially formulated to ensure that belts are sufficiently conductive to avoid the build-up of static electricity. The electrical resistance is determined by passing an electric current of specified voltage between electrodes placed on the surface of the belt. The internationally recognised acceptance criteria for electrical conductivity is a maximum resistance of 3.0 x 108 Ohms (300M Ohms).

QUALITY TESTING

All Fenner belting is produced within our Quality Management System which is compliant with ISO 9001:2015. As part of this system, the quality of all belts is verified prior to despatch by a programme of comprehensive testing. Typically this testing will include:

- dimensional measurements

- warp and weft tensile strengths

- tear strength

- elongation

- cover adhesion

- small scale safety tests (laboratory flame and electrical resistance)

- abrasion resistance

- transverse stability

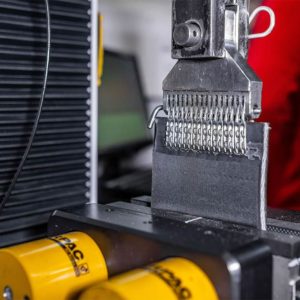

DYNAMIC PERFORMANCE TESTING

In addition to the tests outlined above it is also necessary to ensure that every belt will meet our customers’ requirements and be fit for purpose. The belt’s ability to be joined, either by the use of mechanical fasteners or vulcanised splices, are all tested. Our testing facility is equipped with a range of dynamic test rigs enabling us to perform:

- accelerated life testing on both the belt and related jointing methods

- field problem simulation

- troughing/transition distance evaluations

- product and material development testing

- specific belt testing to individual customer requirements